SIFTING / CLASSIFYING

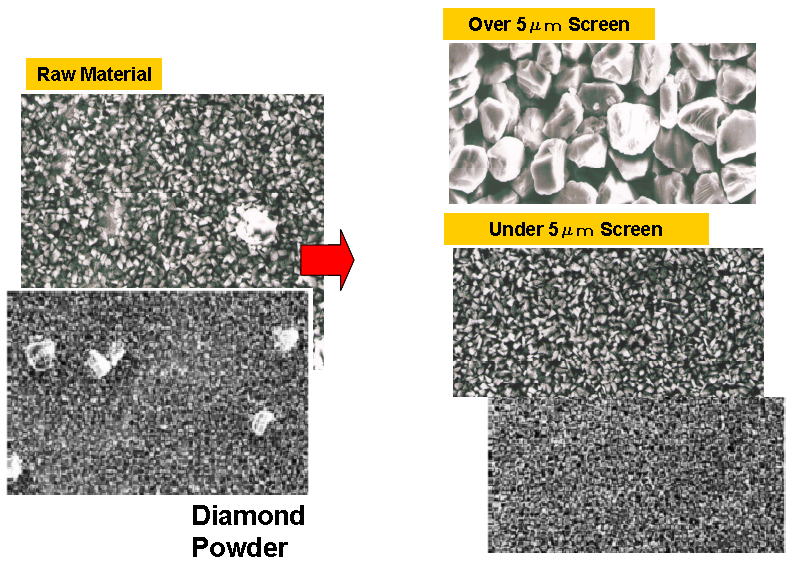

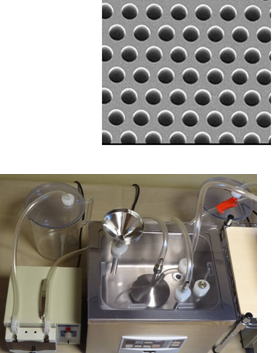

Microclassifier Sifting & Classification System

|

■ Features

Microclassifier Sifting & Classification System, which has been designed

under the long tern fine powder & particles handing experience, and

built with Super Micro Sieve Screen, with “high aspect ratio” & , “ultra

high durablity“, makes 5 micron Screen Classification / Sifting possible.

It can support the industrial requirement for fine powders in sharp-cut

distributed powder & particles.

|

Sifting Finest particles Size : 5μ m

Classification accuracy : hole size ± 0.5μm diameter

Classification speed : 30 ~ 50L/h

Size : Approx. 400 x 500 x 800 (H) mm 50 kg

* Subject to Particle shape, size, distribution, Slurry, viscosity &

other factors (Specification might be changed without notice for the Product

improvement)

|

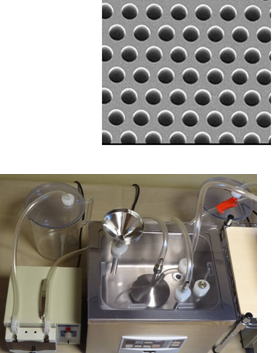

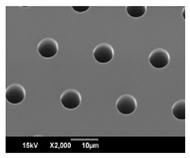

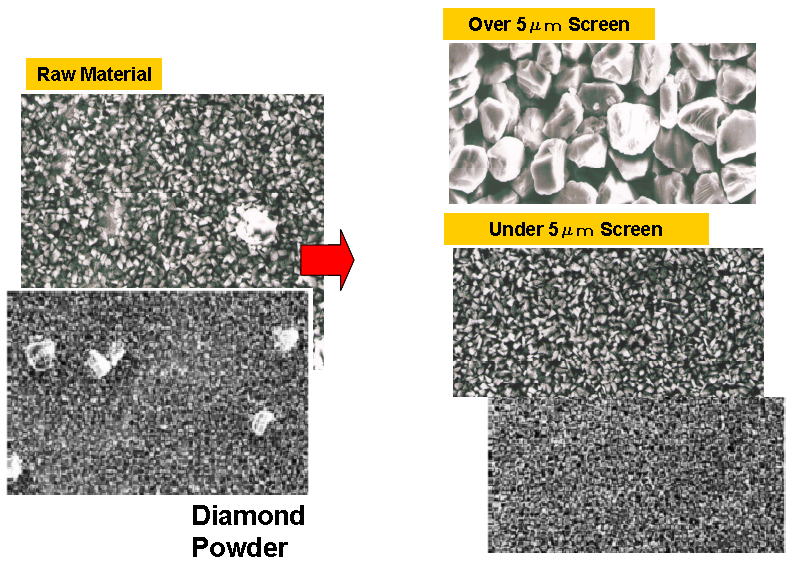

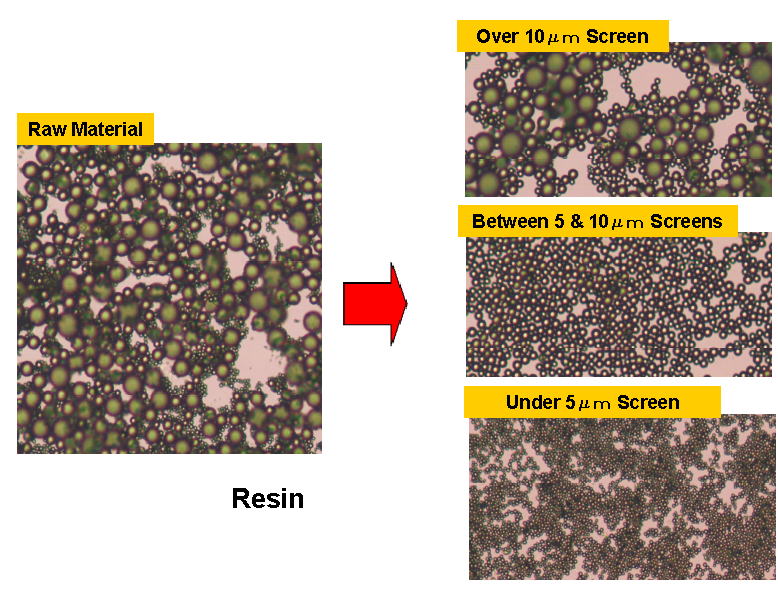

■ Super Micro Sieve Classification

|

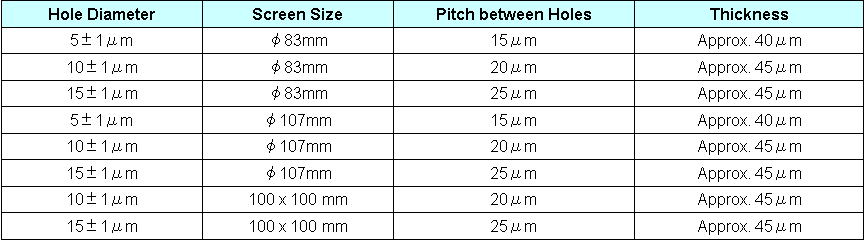

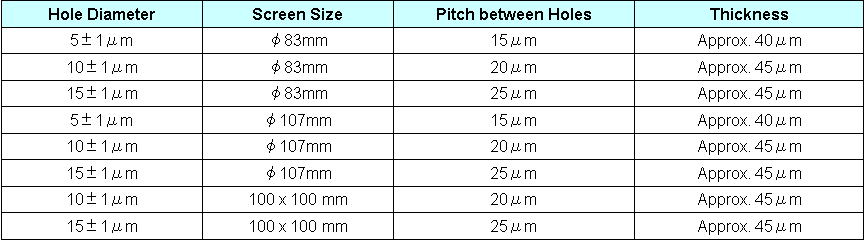

■ Screens for Super Micro Sieve

Material : Nickel Electrodeposit

Hardness : Hv 500

Heat Resistance : Approx. 200

Screen size : 10 ~ 160mm

Thickness : 30 ~ 50μm

|

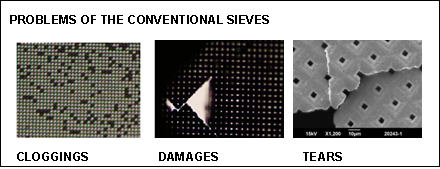

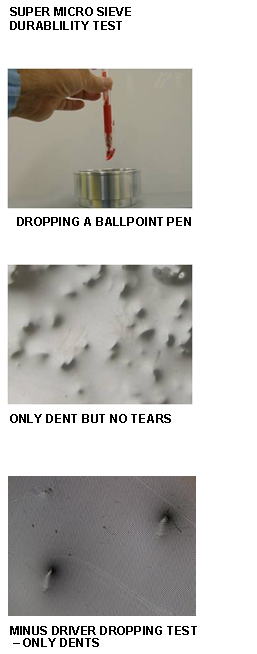

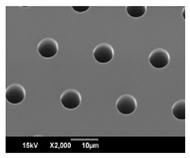

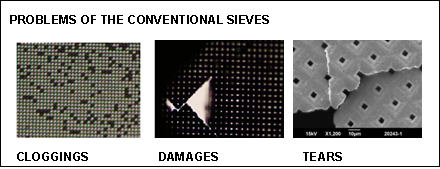

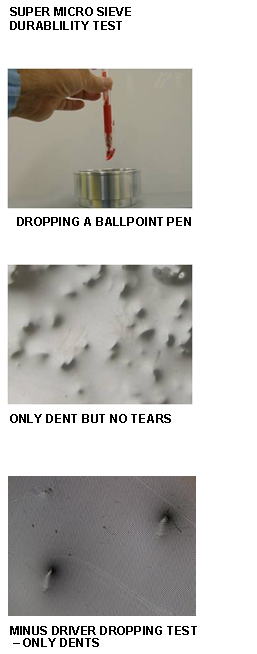

■ High Durability

SUPER MICRO SIEVE HAS ACHIEVED SUCH A HIGH ASPECT RATIO OVER 10, WITH HOLE

DIAMETER Φ5ΜM, THICKNESS 50ΜM, HARDNESS HV600.

IT IS STRONG ENOUGH AND, THE CLEANING BY ULTRASONIC 28 / 45 KHZ 500 W OPERATION

CAN BE DONE.

SUPER MICRO SIEVE HAS ACHIEVED HIGH ASPECT RATIO SCREEN, AND CAN BE USED

FOR THE VARIOUS PARTS OF IMPORTANT APPLICATION OR EQUIPMENT, WHICH ARE

NEEDED THE HIGHEST QUALITY CONTROL.

THE RISKS OF DAMAGES IN OPERATION AND CLEANING ARE SIGNIFICANTLY RECDUCED,

BECAUSE OF THE THICKER SCREEN, WHICH IS PRODUCED BY LARGE CROSS-SECTIONAL

ASPECT RATIO STRUCTURES, AND STRONG STRUCTURE.

|

|

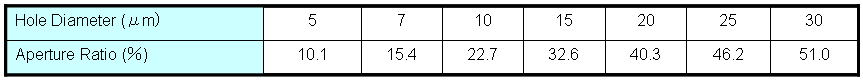

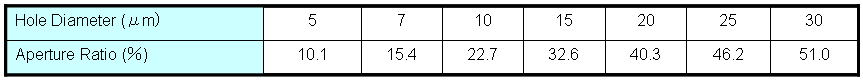

■ High Aperture Ratio

THE HIGH ASPECT RATIO TECHNOLOGY HAS REALIZED A HIGH PITCH STRUCTURE, AND

THE SIEVES WITH Φ10ΜM HOLE DIAMETER IN THE APERTURE RATIO OF 22.7% IS ACHIEVED.

THE ACCURACY, AND HIGH APERTURE RATIO ARE ALSO IMPORTANT FACTORS FOR ACTUAL

SCREEING CAPABILITY FOR FINE POWDERS IN 5 TO 10 MICRON METER SIZE.

SUPER MICRO SEIVES CAN SCREEN FINE POWDERS WITH AT HIGH CAPABILITY, EVEN

WITH SMALLER SIZE.

SUPER MICRO SIEVES, WITH ACCURATE, HIGH DURABILITY, AND HIGH APERTURE RATIO,

REALIZE THE HIGH PRODUCTION EFFICIENCY, WHICH IS REQUIRED FOR THE MANUFACTURING

PROCESS.

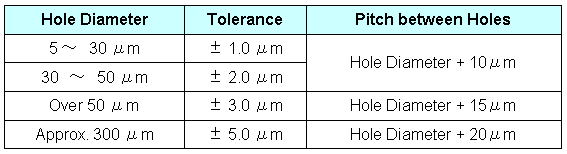

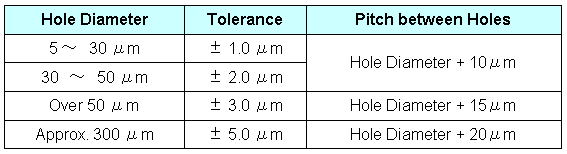

■ Accurate Size, Pitch

THE TOLERANCE OF PITCH BETWEEN HOLES, AND DIAMETER OF HOLES IS KEPT SO

TIGHT, AND REMAINS WITHIN 0.5 MICROM METER.

THE RISK OF HOLE DIAMETER ENLARGEMENT, BY WEARINGS, OR DAMAGES DURING OPERATION,

IS SO LITTLE.

BY THE INGENIOUS SPECIAL METHOD, HIGH ACCURACY IN HOLE SIZE, PITCH, AND

STRONG SCREEN SHEET IS ACHIEVED.

|

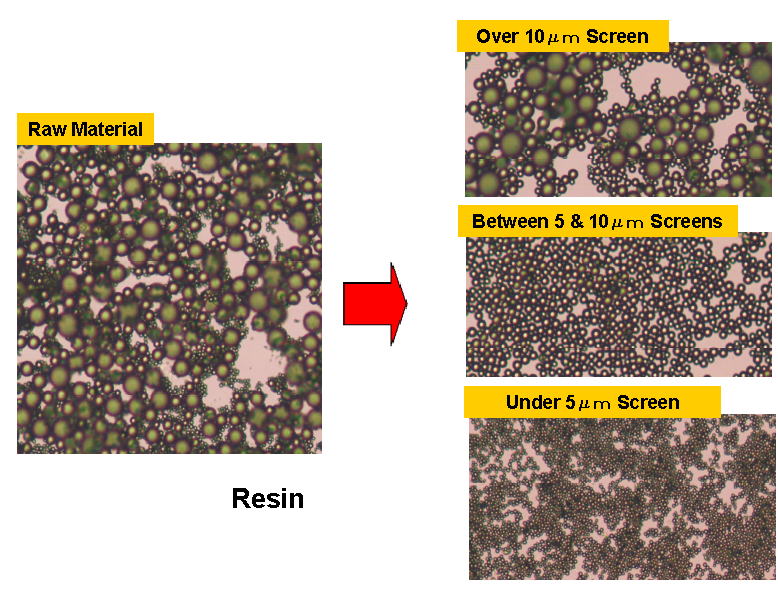

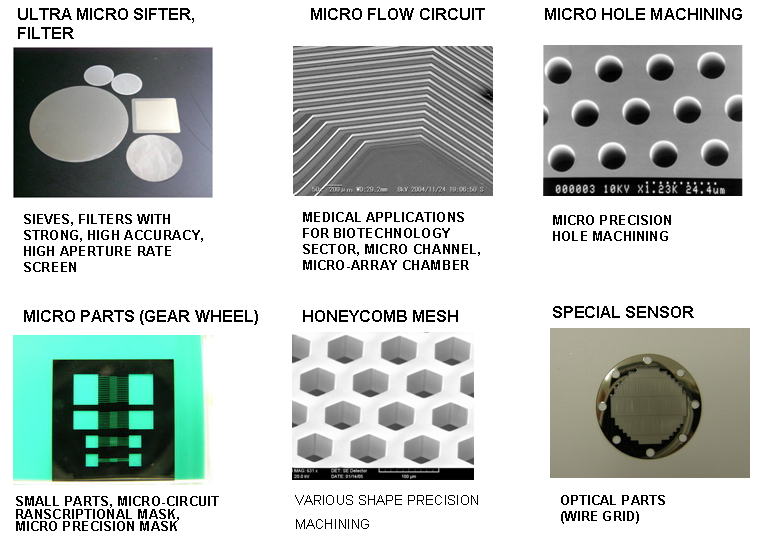

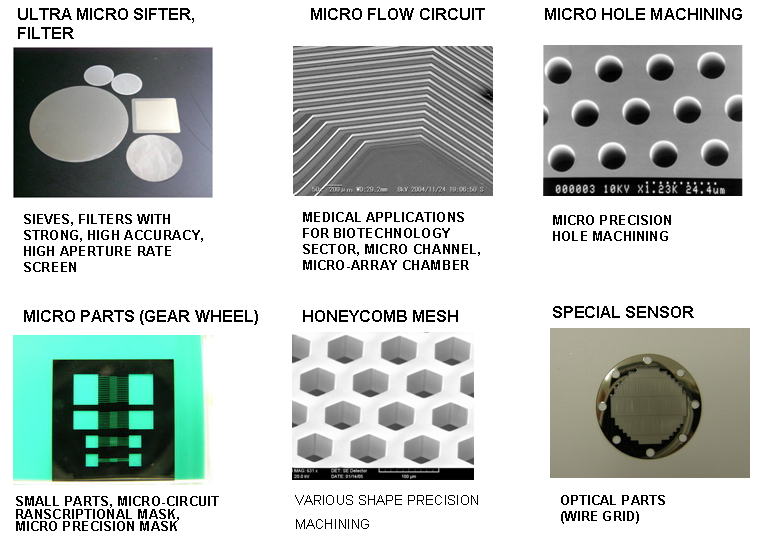

■ Applications

SCREENS, WITH HIGH ASPECT RATIO & ULTRA-HIGH DURABILITY, HAS MADE IT

POSSIBLE TO SCREEN UP TO 5 MICRON METER FINE POWDERS.

MICRO SEPARATING FILTER FOR PLASTICS, DIAMONDS, METALS, AND OTHERS FOR

LITHIUM-ION BATTERIES, ELECTRONICS, AEROSPACE IN VARIOUS FIELDS SUCH AS

ADVANCED MEDICAL TECHNOLOGY, FINE CERAMICS, NEW METALS, POLYMERS.

ELECTROCNIC MATERIALS, COMPOSITE MATERIALS, * FIELD OF PRECISION EQUIPMENT,

MEDICAL EQUIPMENT,

BIOTECH, SENSORS * PARTS FOR ELECTRIC, ELECTRONICS, AUTOMOTIVES

SPRAY NOZZLES FOR DRUG * OPTICS FOR TERAHERTZ-WAVE (WIRE GRID)

CHIP FOR BLOOD ANALYSIS

|

Copyright(C) 2007 FT Associates, Inc. All rights reserved |