NANO GRINDING / CRUSHING / DISPERSING / MIXING<

Beads Mill Nano Grinding System  |

■ Major Applications

BIO INDUSTRY

ENZYMES IN LIVING ORGANISMS, FERNEBTATIONS, BACTERIA DYESTUFF INDUSTRY

DISTRIBUTED DYE, FLORESCENT DYE, HAIR DYE

FINE CHEMICAL INDUSTRY

ACTIVATOR, ANTI-OXIDIZING CHEMICAL, SEALANT, ANTI-FLOWING CHEMICAL FOR PLASMA

DISPLAYS & LIQUID CRISTAL DISPLAYS

CEMENT INDUSTRY

INJECTION CEMENT, SLATE, PILES, SPECIAL CEMENT

BATTERY INDUSTRY

LITHIUM BATTERY, TANTALUM BATTERY, NICKEL HYDROGEN, FUEL BATTERY, SOLAR

BATTERY

FINE CERAMICS INDUSTRY

CERAMIC PASTE, CUMULATIVE LAYER CONDENSER, VARIOUS TYOES OF SEMICONDUCTORS,

OTHER ELECTRINIC PART

PHARMACEUTICAL INDUSTRY

MEDICINE, BIO

PAPER MILL INDUSTRY

PAINTING PAPER, ART PAPER, PRESSURE SENSITIVE PAPER, HEAT SENSITIVE PAPER,

SENSITIVE PAPER

NEW MATERIAL INDUSTRY

LIGHT CATALYST, LIGHT SENSITIVE MATERIAL, LIGHT SENSITIVE DRUM

AGRICULTURAL INDUSTRY

AGRICULTURAL CHEMICALS, FLOWALE CHEMICAL, HYDRATION CHEMICAL, EMULSIFER,

POWER / GAIN CHEMICAL

FIBER INDUSTRY

NYLON THREAD, POLYESTER, ACRYL, FILM

FOOD INDUSTRY

SPICE, CHOCOLATE, MAYONNAISE, FERMENTING/ ADDITIVE, HEALTH FOOD, SOYBEAN

PLOWDER

PIGMENTS / INK / PAINT NDUSTRY

INORGRANIC/ ORGANIC, OXIDIZED TITANIUM, IRON OXIDE, CALCIUM CARBONATE,

INK JET, BALLPOINT PEN, INDIA INC, MARKERS, PAINT,

RUST PREVENTING COAT, ELECTRIC CONDUCTOR, INSULATION

COSMETICS INDUSTRY

CREAM, MANICURE (NAIL POLISH), LIP STICK, FOUNDATION, EYE SHADOW

RECORDING MEDIA INDUSTY

COLOR FILTER, ORGANIC EL, VIDEO TAPE, FLOPPY DISK, PREPAID CARD

|

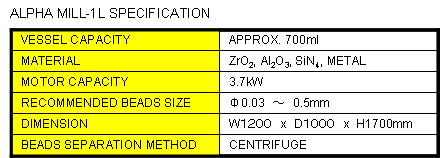

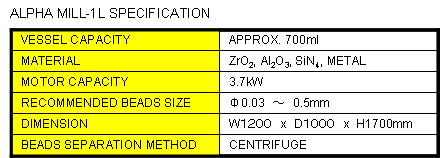

■ Alpha Mill 1L

* CONTINUOUS OPERATION WITH MICRO BEADS (Φ0.03 ~ 0.5mm)

* MOST EFFECTIVE PROCESSING USING ORIFICE

CONTRACTILE FLOW MAKES HIGH-EFFECTIVE

PROCESSING THE PROCESSING TIME IS

CUT BY 50~65%

* HIGH QUALITY PRODUCTION THROUGH UNIFORM

PROCESSING THE MEDIA PACKING PHOENOMINON

IS PREVENTED, BY COMPULSORY BEADS

CIRCULATION. ABNORMAL HEAT, AND WEAR-OUT

IS PREVENTED. SHARP PARTCLE DISTRIBUTION IS

ACHIEVED BY IDEAL BEADS CIRCULATION

* LONGER MACHINE LIFE BY LESS WEAR-OUT

DESIGN NEW LESS WEAR-OUT DESIGN MAKES

ROTOR LIFE LONGER, AND PREVENTS RAPID

PERFORMANCE DETERIORATION

|

|

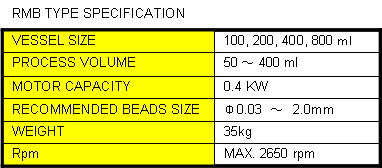

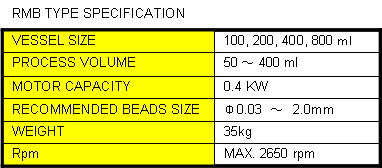

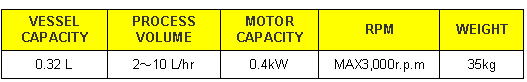

■ Batch type Ready Mill (Model RMB)

BEST LABORATORY BEADS MILL FOR EXPERIMENTAL USE

VERY SIMPLE & EASY OPERATION FOR DATA COLLECTION VERY SIMSPLE BUT EFFECTIVE

STRUCTURE FOR OVERHAUL & ASSEMBLY, AND CLEANING IT WORKS WITH 100V

POWER SUPPLY

HIGH COST PERFORMANCE SIMPLE STRUCTURE AT VERY REASONABLE PRICE & OPERATION

COST WITH HIGH PERFORMANCE.

WIDE VARIATION, OPTIONS WIDE RANGE OF VESSLE SIZE IS AVAILABLE MANY OPTIONS

IN MATERIALS, ATTACHMENT, SPECIFICATIONS, ARE AVAILABLE

SMALL SAMPLE TEST CAN BE DONE WITH ONLY 30ML SLURRY SAMPLE )

|

|

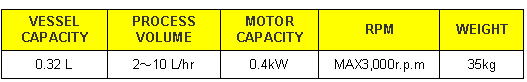

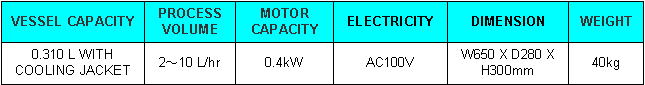

■ Continuous Vertical-Type Ready Mill (Model RMV-03)

CONTINUOUS TESTS CAN BE MADE WITH SMALL VOLUME SAMPLES.

THE INEXPENSIVE, HIGHLY COST-EFFECTIVE COMPACT MILL IS REALIZED.

THE CLEANING OF COMPONENTS IS SO EASY, AND CAN BE USED FOR A WIDE RANGE,

& PURPOSE OF TESTS.

IT CAN BE SCALED UP FOR A PRODUCTION UNIT WITHOUT PROBLEMS. * IT CAN BE

USED AS A BATCH-TYPE MILL.

φ0.3mm TO 2.0mm BEADS CAN BE USED.

|

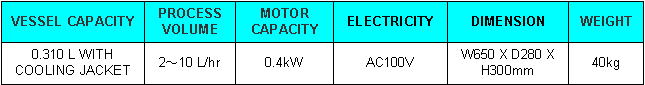

■ Continuous Horizontal-Type Ready Mill (Model RMH-03)

IT IS SUITABLE FOR TEST OPERATION & SMALL SIZE PRODUCTION.

φ0.2 TO 2.0mm BEADS CAN BE USED. * THREE KINDS OF SHAFT SEATS CAN BE SELECTED.

MANY OPTIONS CAN BE OFFERED FOR SHAFT SEAL TYPE, ELECTRICAL SPECIFICATION,

PUMP TYPE, CONTROL PANELS, MONITORING

SYSTEMS, AND OTHERS.

|

■ Ultra Visco Mill (Model UVM Series)

0.2mm BEADS CAN BE USED.

SLURRY WITH HIGH VISCOSITY CAN BE PROCESSED.

BY SEPARATING THE GAP SEPARATOR MOVEMENT FROM AGITATION AXEL, IT ACHIEVES

THE

SLOW ROTATION OF SEPARATOR, AND MINIMIZES THE SLIT SPACE.

THE DISK WITH PINS CREATES HIGHLY EFFECTIVE PULVERIZING POWER.

THE INCORPORATION OF THE DISK WITH PINS ENABLES A HIGH PULVERIZATION EFFETS

BY

DISK SPEED OF 6 TO 12 m/sec, AND THIS MODERATE ROTATION SPEED DECREASES

THE

ABRASION OF THE MECHANICAL PARTS & BEADS, AND GENERATION OF THE HEAT.

THE LESS CLOGGING OF SLURRY EMISSION SLIT ALLOWS A LARGE AMOUNT OF PROCESSING

FLUIDS. THE LESS FORM GENERATION IN SLIT MAKES THE BETTER PROCESSING FOR

FORM-GENERATING FLUIDS.

APPLICATIONS :

FOR THE PULVERIZATION, CRUSHING, DISPERSION, AGITAION &

SOLIDIFICATION OF COSMETICS, DYE, INKS, CARBON, PAINT,

PAPER COATING MATERIAL, CERAMICS, MAGNETIC PAINT, ELECTONIC

MATERIAL, FIBER, LIGHT SENSITIVE MATERIAL, BATTERIES, LIGHT

CATALYSTS, AGRICULTURAL CHMICALS, MEDICINE, FOOD, & OTHERS

|

|

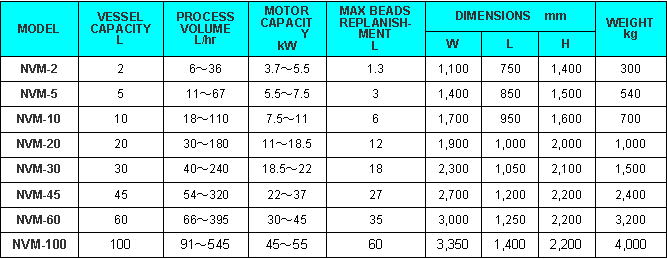

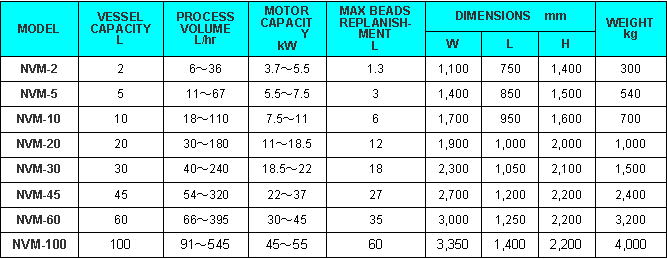

■ New Visco Mill (NVM / NVM-2)

φ0.45mm BEADS CAN BE USED.

IT ACHIEVES THE SLOW ROTATION OF SEPARATOR

THE INCORPORATION OF THE DISK WITH PINS ENABLES A DISK SPEED OF 6 TO 12

m/sec, AND HIGHER REPLENISHMENT RATIO OF SMALL BEADS.

IT REALIZES THE HIGH PERFORMANCE MODEL, WITH LOW ABRASION, LOW HEAT GENERATION,

AT LOW COST.

THE INCORPORATION OF THE DISK WITH PINS ENABLES A HIGH PULVERIZATION EFFETS

BY DISK SPEED OF 6 TO 12 m/sec, AND THIS MODERATE ROTATION SPEED DECREASES

THE ABRASION OF THE MECHANICAL PARTS & BEADS, AND GENERATION OF THE

HEAT.

IT IS DESIGNED FOR THE SIMPLE STRUCTURE AND EASY MAINTENANCE AT A REASONABLE

INITIAL AND RUNNING COST.

APPLICATIONS : SAME AS THE ULTRA VISCO MILLS

|

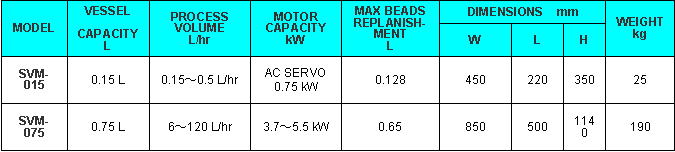

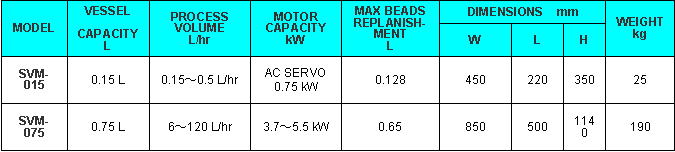

■ Soft-Fine Visco Mill (SVM)

SOFT DISPERSION TYPE FOR RE-CONDENSED PARTICLES

IT WAS DEVELOPPED TO PREVENT RE-CONDENSATION OF THE FINE PARTICLES.

THE SOFT-FINE VISCO MILLS ARE APPLICABLE FOR RELATIVELY SOFT PARTICLES.

THE LOW VISCOSITY OPERATION CAN BE EXPECTED IT CAN BE USED FOR NANO LEVEL

PULVERIZING OF SOFT MATERIALS. THE MATERIAL IS ONCE SENT TO THE DISPERSANT

CONTAINER IMMEDIATELY AFTER THE GRINDING TO OPTIMIZE THE EFFECTS OF THE

DISPERSAN, AND THE RESEND THE MILL FOR ADDITIONAL GRINDING.

THE SOFT PULVERIZING PROCESS LASTS LONGER WITH LESS SCRUBBING, AND CONTAMINATION.

|

■ Screenless-type Sand Grinder (SLG)

IT CAN BE USED FOR HIGH VISCOSITY UP TO 10,000cp MATERIALS.

THE SEPARATION OF THE PROCESSING SLURRY AND BEADS IS DONE THROUGH AN ADJUSTABLE

SLIT (GAP SEPARATOR) AT THE UPPER PART OF THE VESSEL,ANDO NO SCREEN IS

USED.

■ Open-type Sand Grinder (SLG)

360 DEGREES SCREEN IS LOCATED AT THE UPPER PART OF THE VESSEL

THE CONDITION OF THE PROCESSING FLUILDS, COMING OUT FROM THE SCREEN CAN

BE OBSERVED FROM OUTSIDE.

■ Closed-type Sand Grinder (ESG)

IT IS DESIGNED AND DEVELOPPED FOR LOW VISCOSITY, HIGH VOLATILE SLURRY.

IT CAN BE USED FOR THE VISCOSITY UP TO 5,000cp MATERIALS.

THE MACHINE IS TOTALLY CLOSED FROM OUTSIDE AIR TO AVOID THE CLOGGING BY

DRYING OF HIGH VOLATILE SOLVENTS.

APPLICATIONS :

PIGMENT, DYE, CARBON, HEAT SENSITIVE MATERIAL, ELECTRONICS

MATERIALS, DRUG, FOOD, COSMETICS, INK, PAINT, & OTHERS

|

|

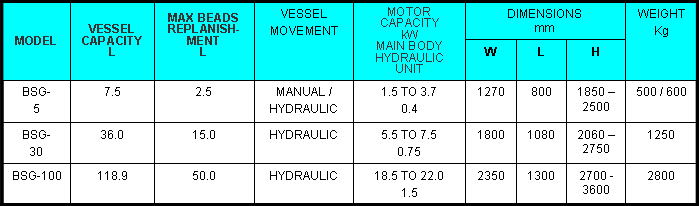

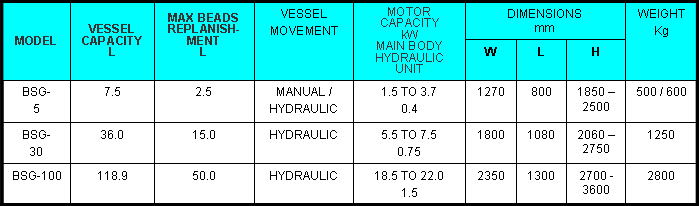

■ Batch-type Sand Grinder (BSG)

IT IS SUITABLE FOR TEST & SMALL SIZE DISPERSING AND GRINDING OPERATION.

ULTRA SMALL BEADS (φ0.1mm) CAN BE USED.

THE OPERATION IN COOLING CONDITION CAN BE OFFERED.

AGITATION SHAFT & VESSEL CAN BE MOVED.

ALL PROCESSING FLUIDS CAN BE COLLECTED AFTER THE OPERATION.

THE INCORPORATION OF THE DISK WITH PINS ENABLES A HIGH PULVERIZATION EFFETS

BY DISK SPEED OF 6 TO 12 m/sec, AND THIS MODERATE

ROTATION SPEED DECREASES THE ABRASION OF THE MECHANICAL PARTS & BEADS.

* THE DE-FORMING AND DISPERSION IN VACUUM

CONDITION CAN BE OFFERED (OPTION).

|

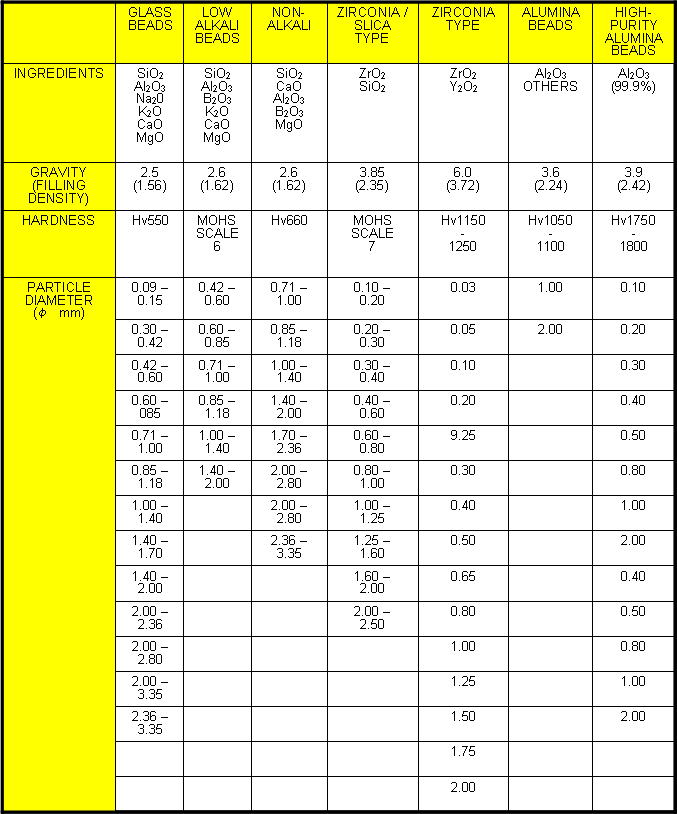

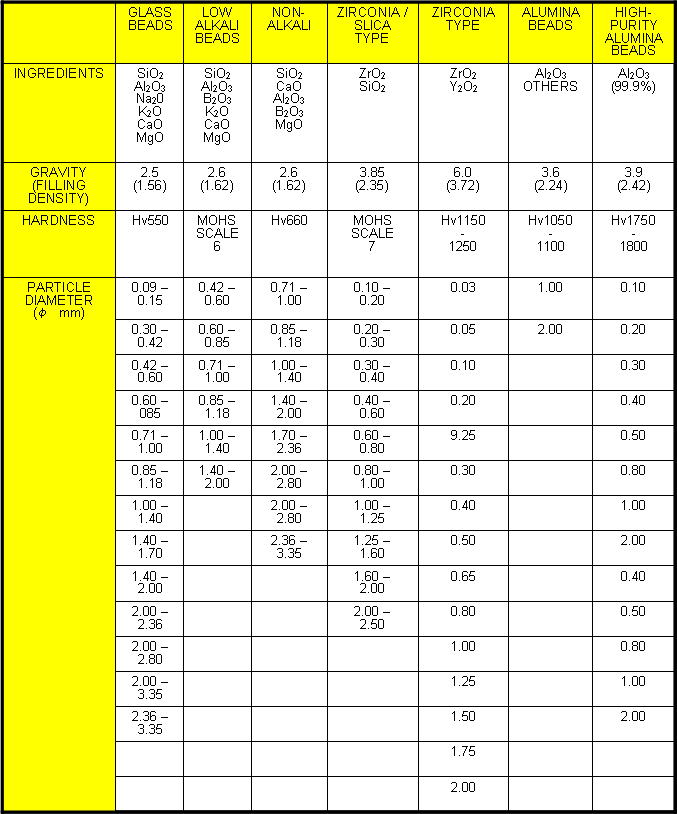

■ Beads Selection

|

Copyright(C) 2007 FT Associates, Inc. All rights reserved. |