GRINDING, CRUSHING

Jet Mill Ultra Fine Grinding System  |

■ Features

GROVE BOX TYPE

SMALLEST MODEL

MC44 R&D TYPE

|

Micromacinazione SA in Switzerland has wide and many experiences for Ultra

Fine Grinding, based on the know-hows through the actaual Grinding Services,

approved

by the governmental authorities in Europe. USA. Janan, and

others for Pharmaceutical Industries in the world.

The high quality and performance models with the technical /

engineering support are proposed to the customers in the

advanced and leading industires in the world, which can

support the demands of high-quality powder grinding for

food materials, Chemical, Metals, Ceramics, and others

The system is developed and designed for the fine and high

quality powders. Especially it is featured for preventing contamination,

easy cleaning, simple assembly and disassembly.

This is a dry jet mill pulverizing system, which meet the high

requirement for such as quarantine, high quality without

contamination, particle sizes,and so on.

In addition to the manufacturing and sale of Jet Mill Grinding

System, the company has been engaging in the Grinding Service

for Permaceutical materials under the periodic inspection by the

Governmental Authorities like Swissmedic, FDA, and Japanese Ministry of

Health, Labor and Welfare, and also the system is

corresponding to cGMP.

Also the explosion-proof and oil-free motor type, with a high

degree of accuracy, and volumetric feeder, and other optional equipment,

sub-systems, and various glove box (insulators for

gas purge operation or priventing material scattering) have been

offered to fillthe customer requirement.

The performance at sub-micron-and nano level grinding, by

laboratory test system, can be assured in the operation

by the medium and large production machine.

Grindning by High Pressure Air or Gas (using the kinetic

energy), without Grinding Media

Ultrafine particles for new structural material can be created

with less contamination

Stable continuous grinding is possible.

Nitrogen gas purged Grinding is also available

* Improve the crushing treatment capacity

* ensure continuous operation

* keep high screening efficiency

* lower the wearing of the wall surface

* reduce chamber wall damage

* create fine powders in various types of crushed

material having different physical properties

* control freely the range of grain size distribution

|

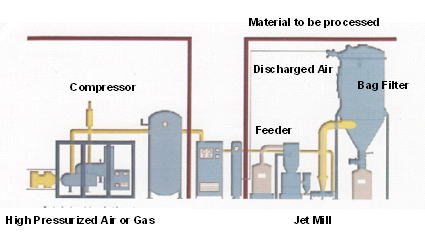

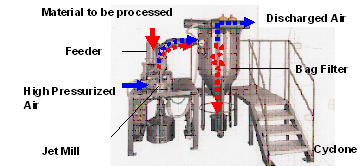

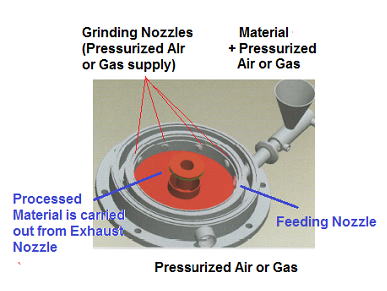

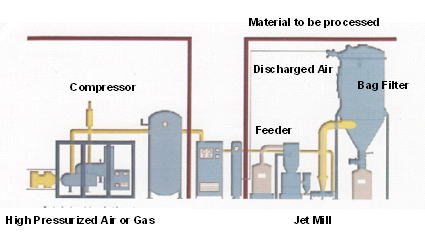

■ System Concept

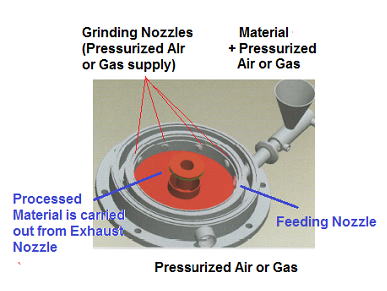

THE RAW MATERIALS CARRIED INTO THE MILL ARE GROUND BY HIGH PRESSURIED,

STABLE CONCENTRIC VORTEX AIR FLOW.

THE JOULE-THOMSON EFFECT ALLOWS MATERIALS TO BE PROCESSED WITHOUT UNDERGOING

A RIZE IN TEMPERATURE.

THE IDEAL AIR FLOW REDUCES THE COLLISION OF RAW MATERIALS TO THE WALL,

ACCUMULATION OF RAW MATERIALS IN THE CHAMBER, ALSO LESSENS THE CONTAMINATION.

GRINDING NOZZLES AND FEEDING NOZZLE ARE SET AROUND JET MILL, AND MAKES

THE HIGHLY PRESSURIZED, STABLE, CONCENTRIC VORTEX OF AIR / GAS.

THE RAW MATERIAL IS FED INTO THE CHAMBER THROUGH FEEDING NOZZLE.

THEN PROCESSED MATERIAL IS CARRIED OUT FROM THE EXHAUST NOZZLE.

|

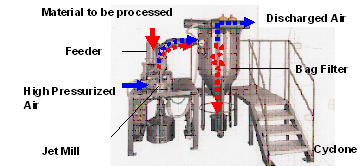

The raw materials are carried into the Jet Mill by the Feeder and supplied

to the Grinding Chamber through the Feeding Nozzle.

Pressurized Air or Gas from the Compressor is regulated by the Receiver

Tank, and sent to the Grinding Chamber through the Nozzles.

Raw materials are caught up in the high-speed airflow, and ground into

nanometer-sized particles by friction, and by the impact caused by the

collision of particles.

The particles with lower weight gather in the center of the vortex, and

are sucked up in the high-speed airflow and sent to the Cyclone, where

relatively larger size of the processed material is separated into the

container.

Finer particles, which can not be seized at the Cyclone, are carried into

the Bag Filter, and screened at filters. Air passes through filters, and

discharged outside.

|

■ Applications

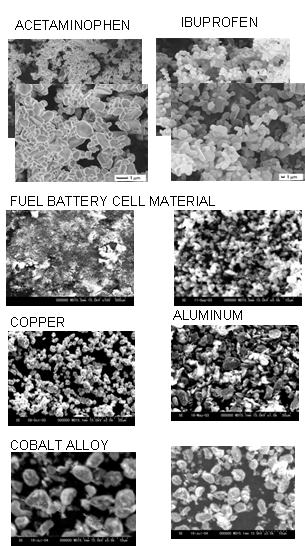

Rare Metals, Cobalt, Cupper, Ferrite, Titanium, Indium, PZt,

Others for FuelBattery Cell, Electrode, Electronics & Other Divices

Cosmetics, Pharmaceutical Materials, Foundation, Medical Materials,

Silk Powders, & Others for Cosmetics, Drags & Others

Food, Health Food, Fish Bone, Tea, Rice Powders & Others for

Food Additives & Other Substitutes

Chemical Materials, Fillers, Fluorescent, Dyes, Paint, Wax, Prastics,

Silica Gell, and Others for Chemical Applications

|

|

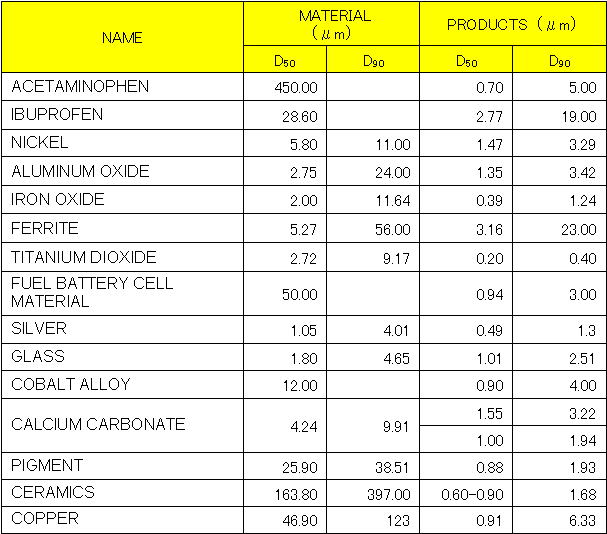

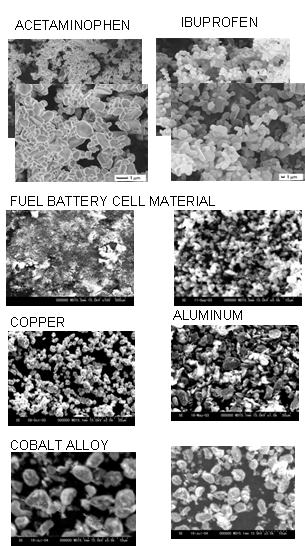

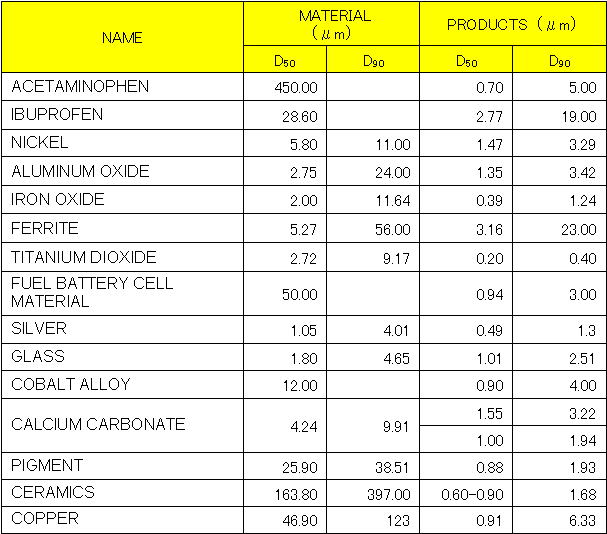

■ Test Data

|

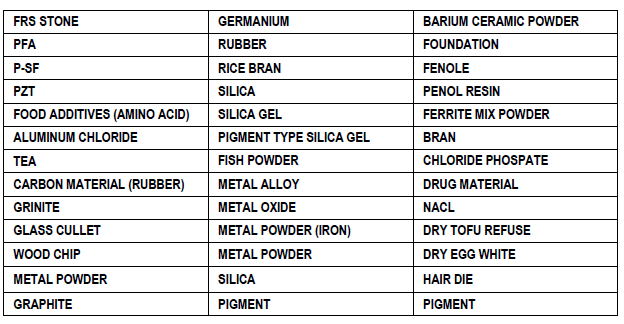

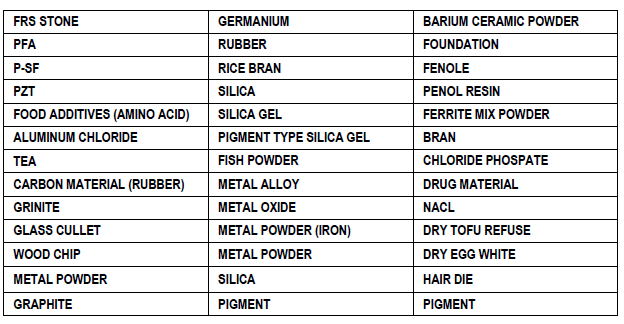

■ Materials Processed

|

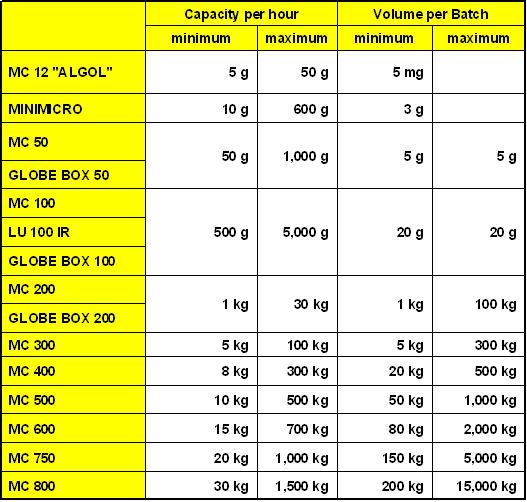

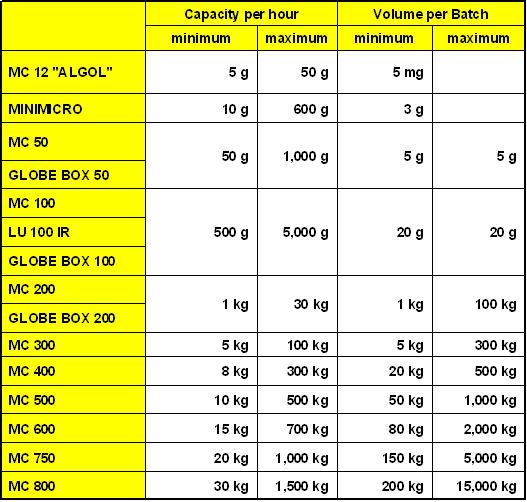

■ Lineup

|

■ Grove Box for Jet Mill Operation

For the field of pharmaceutical raw materials, Globe Box (Isolator) is

offered

prevent fine powder scattering, and isolating materials from the outside

air.

|

|

Copyright(C) 2007 FT Associates, Inc. All rights reserved |