|

Nano Creating System ・ Powder & Particles Processing System

|

|

FT Associates, Inc. (FTA)

|

|

|

1-23-6 Higashi-Fujisawa, Iruma-shi, Saitama 358-0012, Japan

Phone : 81-4-2997-8070 / Fax : 81-4-2997-8079 / E-Mail : sales@ftajapan.com / URL : http://www.ftajapan.com |

| HOME | INFORMATION & DATA | JAPANESE | ||

| CAVITATION MILL | ULTRASONIC PROCESSOR | BEADS MILL | JET MILL | |

| MICRO CLASSIFIER | HYDROCYCLONE | VIBRATION SIFTER | AIR CLASSIFIER | |

* Cavitation Mill * Ultrasonic Processor * Jet Mill * Beads Mill * Micro Classifier * Hydrocylone * Vibration Sifter * Air Classifier |

Nano Creating & Powder & Particles Processing System Products & Service In the area of Powder & Particles processing, FT Associates, Inc.(FTA) has been working aggressively, to support the customers requirement for Nano / Sub Micron Powder & Particles Creating System & Services in Grinding, Dispersing, Classification, and other powder processing area. We believe our activities; engineering, sales and other services, with our business associates in manufacturing of such fine Powder Processing Systems and Equipment , can be a best approach for the final solutions, which has been looking for, by the companies at the front line of the current industries. |

| Nano Dispersing / Emulsifying Wet Operation |

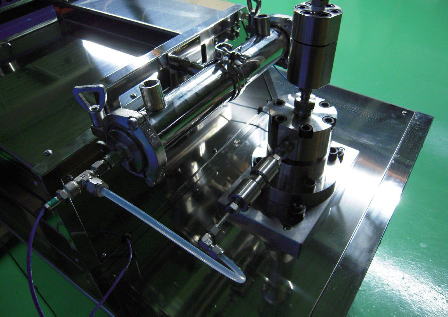

Cavitation Mill Nano Dispersing System

* CRISTAL & SURFACE OF THE MATERIAL IS NOT DAMAGED * THE SHARP PARTICLE DISTRIBUTION IS IMPROVED * CONTINUOUS OPERATION UNDER VERY SIMPLE PROCEDURE IS ENSURED * PURE MATERIALS WITHOUT CONTAMINATION CAN BE PRODUCED * VARIOUS RANGE OF PARTICLES WITH ADJUSTABLE PRESSURE RANGE CAN BE CREATED   |

| Nano Dispersing / Emulsifying, Nano forming / Crushing / Degassing &others Wet Operation |

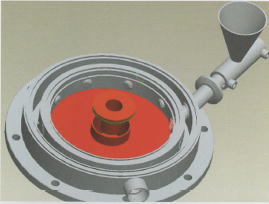

The Ultrasonic Processor Nano Forming System

* NO ENERGY LOSS OCCURRED BY INTERNAL HEAT GENERATION, AND HIGH EFFICIENCY IS ACHIEVED. * 24 HOURS CONTINUOUS OPERATION IS AVAILABLE. * THE OUTPUT PER UNIT IS HIGH, AND THE LARGER SIZE PIPES CAN BE USABLE TO MAKE CLOGGING FREE. * NO MOVING PART IS ADOPTED, AND MAKE OVERHAUL AND CLEARING SO EASY AND SIMPLE.   |

| Sub Micron Grinding Dry Operation |

Jet Mill Ultra Fine Grinding System * THE HIGH QUALITY & PERFORMANCE MODELS ARE PROPOSED. * PROFESSIONAL TECHNICAL / ENGINEERING SUPPORT ARE PROPOSED TO CUSTOMERS IN ADVANCED AND LEADING INDUSTRIES IN THE WORLD, * IIT CAN SUPPORT THE DEMANDS OF HIGH-QUALITY POWDER GRINGING FOR FOOD MATERIALS, CHEMICAL, METALS, CERAMICS, AND OTHERS.    |

| Nano Grinding / Dispersing Dry Operation |

Beads Mill Nano Grinding & Dispersing System * CONTINUOUS OPERATION WITH MICRO BEADS (Φ0.03 ~ 0.5mm) CAN BE DONE * HIGH-EFFECTIVE PROCESSING, AND HIGH QUALITY PRODUCTION THROUGH UNIFORM PROCESSING IS ACHIEVED * ABNORMAL HEAT, AND WEAR-OUT IS PREVENTED * SHARP PARTCLE DISTRIBUTION IS ACHIEVED BY IDEAL BEADS CIRCULATION * LONGER MACHINE LIFE BY LESS WEAR-OUT DESIGN IS ACHIEVED. * RAPID PERFORMANCE DETERIORATION IS PREVENTED * SLURRY WITH HIGH VISCOSITY CAN BE PROCESSED.  |

| Sub Micron Classification / Sifting Wet Operation |

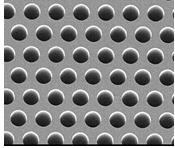

Micro Classifier Sifting & Classificatiaon System * "HIGH ASPECT RATIO", AND "ULTRA HIGH DURABILITY" SUPER MICRO SIEVE SCREEN IS ADOPTED * 5 MICRON METER SCREEN CLASSOFICATION / SIFTING / POSSIBLE. * CONTINUOUS STABLE OPERATION IS AVAILABLE * CLEAR CUT CLASSIFICATION CAN BE EXPECTED.   |

| Sub Micron Classification / Sifting Wet Operation |

Hydrocylone Classification System * CLASSIFICATION / SEPARATIONS SIZED 0.5 - 150 MICRONS PARTICLES CAN BE DONE AT LOW COST * VERY STABLE, SIMPLE AND EASY OPERATION IS OFFERED * FREE FROM PROBLEMS LIKE SCREEN DAMAGES OF VIBRATING SCREEN * SELECTED MATERIAL ARE USED AGAINST HIGH ABRASION NATURE BIG SIZE, OR METAL PARTICLES * EFFECTIVE OPERATIONFOR TO REOVE CHIPS, AND FRAGMENTS FROM LAPPING, POLISHING PROCESS * HIGH REMOVAL EFFICIENCY, 50 TO 80% RECOVERY OF ABRASIVE POWDER  |

| Classification / Sifting Dry & Wet Operation |

Powder & Particles Vibration Sifter * VARIOUS MODEL CHOICE FOR MATERIAL CHARACTALISTIC IS AVAILABLE * OUTLEY POSITION IS ADJUSTABLE * NO EXTRA INSTALLATION WORK IS REQUESTED * BOTH DRY AND WET OPERATION IS ACCEPTABLE * EASY SCREEN CHANGE IS REALIZED * LESS MESH BLOCKING OR CLOGGING BY USING ULTRA SONIC VIBRATION * SEPARATING MOTION IS SLECTABLE  |

| Classification / Sifting Dry Operation |

Micro Powder Air Classifier * WIDE RANGE OF CLASSIFICATION POINT (0.5〜50 μm) CAN BE APPLIED * VERY SHARP AND ACCURATE CLASSIFICATION IS ACHIEVED * LESS CONTAMINATION, LESS MACHINE WEAR CAN BE EXPECTED * COMPACT DESIGN ACHEIVES EASY AND SIMPLE CLEANING AND MAINTENANCE   |

| Copyright(C) 2007 FT Associates, Inc. All rights reserved |

|