CLASSIFICATION / SEPARATION / CONCENTRATION

Hydrocyclone Classification System  |

|

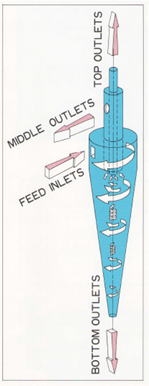

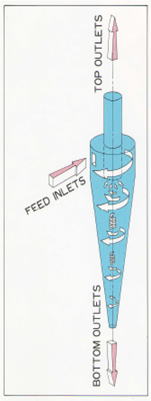

■ Principles of Hydro-Cyclone

WHEN SLURRY IS INTRODUCED TO THE HYDRO-

CYCLONE, ACCORDING TO CENTRIFUGAL FORCE,

LARGE PARTICLES IN THE SLURRY ARE FORCED

TO THE WALL.

AND GOING DOWNWARD IN THE GRAVITATIONAL

DOWN STREAM, AND DISCARGED FROM THE

BOTTOM NOZZLE.

SMALL PARTICLES IN SLURRY ARE CAUGHT IN

UPWARD STREAM IN THE CENTER OF THE CYLONE

AND DISCHARGED AT THE TOP NOZZLE.

|

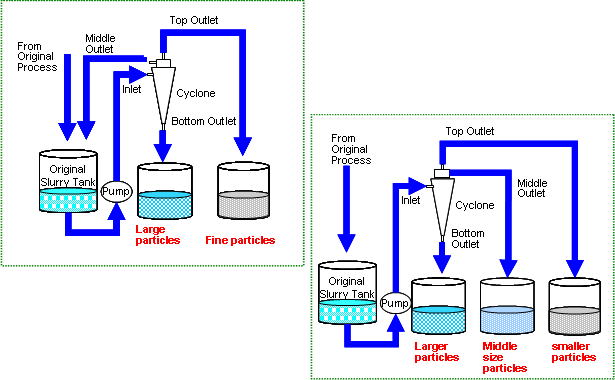

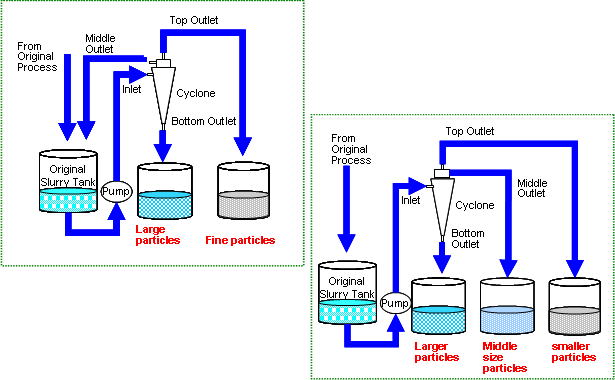

3-OUTLET 2-OUTLET

|

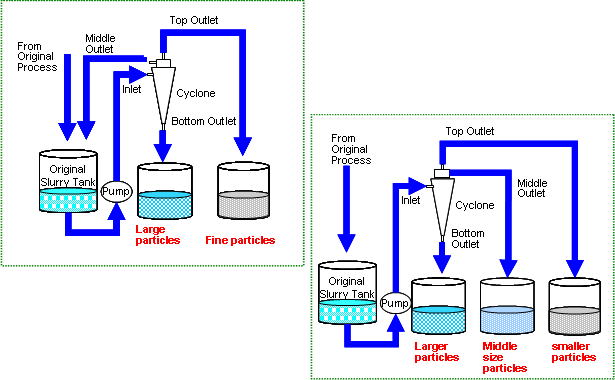

■ Hydro-Cyclone System

3-OUTLET HYDRO-CYCLONE SYSTEM

* FOR SEPARATION AND CLASSIFICATION OF

SMALL PARTICLE

* VERY HIGH CLASSIFICATION ACCURACY

REQUIRED

* REMOVAL AND COLLECTION OF SMALL PARTICLE

* FOR HIGER YIELD RATE OF LARGE PARTICLE

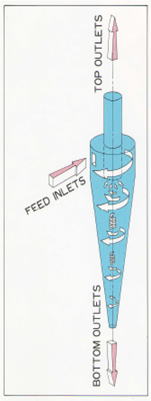

2-OUTLET HYDRO-CYCLONE SYSTEM

* FOR SEPARATION, CLASSIFICATION, AND

CONCENTRATION OF MIDDLE TO LARGE SIZE

PARTICLES

* FOR LARGE FLOW RATE OPERATION

* FOR WIDER RANGE SEPARATION

* FOR REMOVAL OF LARGER SIZE PARTICLES

|

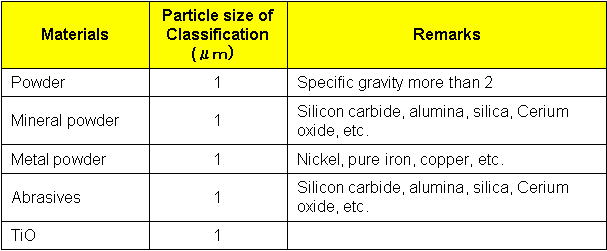

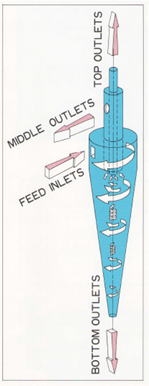

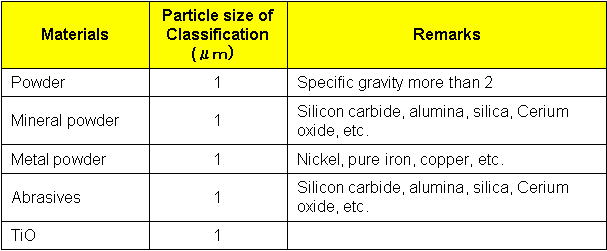

■ 3-Outlet Hydro-Cylone System

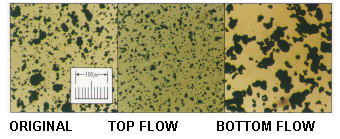

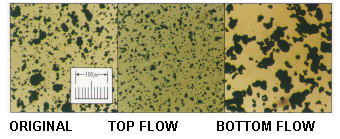

IN HYDRO-CYLONE, HIGHER DENSITY SLURRY FLOW, CONTAINS LARGER SIZE PARTICLE,

IS EXHAUSTED THROUGH BOTTOM OUTLET, WHILE LOW DENSITY SLURRY FLOW, CONTAINS

SMALLER SIZE PARTICLES, GOES THROUGH THE TOP OUTLET TO OUTSIDE.

IN THREE-OUTLET CLASSIFICATION TYPE HYDRO-CYCLONE SYSTEM, MIDDLE OUTLET

IS NEWLY BUILD, IN ADDITION TO TOP OUTLET, AND BOTTOM OUTLET NOZZLE.

THROUGH THE MIDDLE OUTLET, SLURRY WHICH CONTAINS THE SOLIDS, AND VERY CLOSE

TO THE ORIGINAL SLURRY IS EXHAUSTED, AND AGAIN RETURNED BACK TO CYCLONE

WITH THE ORIGINAL SLURRY.

THIS THIRD FLOW THROUGH THE MIDDLE OUTLET CAN MAKE MUCH HIGHER AND ACCURATE CLASSIFICATION.

Model : TR-5

* Classification / Separation Particle size : 0.5 - 5 μm

* Flow rate Per Cyclone : 3.5 L / min

* Inlet Pressure : 0.6 MPa

* Application: Classification of Fine Particle, Polishing Slurry Recycling

|

■ 3-Outlet Hydro-Cylone System

IN HYDRO-CYLONE, HIGHER DENSITY SLURRY FLOW, CONTAINS LARGER SIZE PARTICLE,

IS

EXHAUSTED THROUGH BOTTOM OUTLET, WHILE LOW DENSITY SLURRY FLOW, CONTAINS

SMALLER SIZE PARTICLES, GOES THROUGH THE TOP OUTLET TO OUTSIDE.

IN THREE-OUTLET CLASSIFICATION TYPE HYDRO-CYCLONE SYSTEM, MIDDLE OUTLET

IS NEWLY

BUILD, IN ADDITION TO TOP OUTLET, AND BOTTOM OUTLET NOZZLE.

THROUGH THE MIDDLE OUTLET, SLURRY WHICH CONTAINS THE SOLIDS, AND VERY

CLOSE TO THE

ORIGINAL SLURRY IS EXHAUSTED, AND AGAIN RETURNED BACK TO CYCLONE WITH

THE ORIGINAL

SLURRY.

THIS THIRD FLOW THROUGH THE MIDDLE OUTLET CAN MAKE MUCH HIGHER AND ACCURATE

CLASSIFICATION.

Model : TR-5

* Classification / Separation Particle size : 0.5 - 5 μm

* Flow rate Per Cyclone : 3.5 L / min

* Inlet Pressure : 0.6 MPa

* Application: Classification of Fine Particle, Polishing Slurry Recycling

|

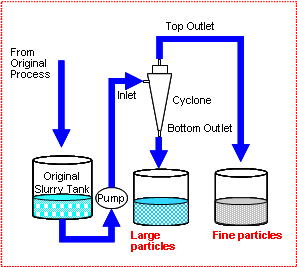

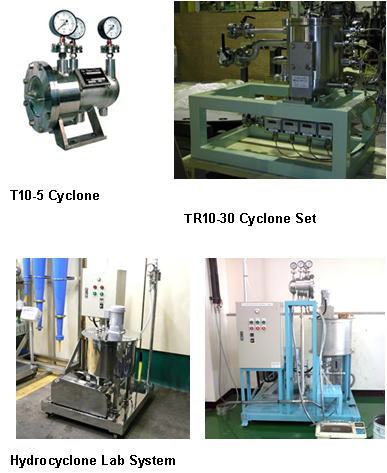

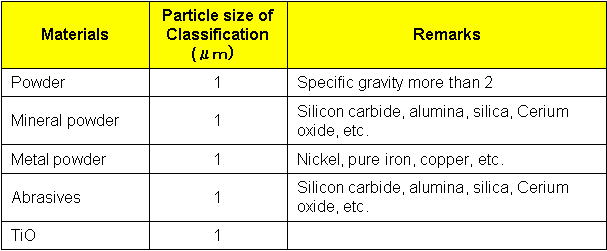

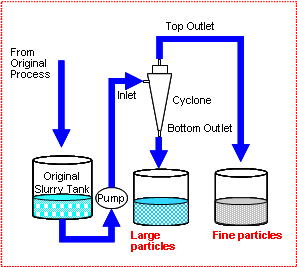

■ 2-Outlet Hydrocylone System

BASED ON THE LONG AND ESTABLISHED EXPERINCE FOR OVER 1500 SETS OF SALES,WIDE

RANGE OF HYDRO-CYCLONES CAN BE OFFERED HIGH VOLUME PROCESSING CAN EXPECT

A HIGH

YIELD.

BROAD RANGE OF CLASSIFICATION, 3μm TO 150μm, CAN BE DONE AT LOW ENERGY

COST

Model : T-5

* Classification / Separation Particle size : 1 - 5 μm

* Flow rate Per Cyclone : 3 L / min

* Inlet Pressure : 0.4 MPa

* Application : Classification, Concentration of Fine Particle

Model : T-10

* Classification / Separation Particle size : 3 - 20 μm

* Flow rate Per Cyclone : 10 L / min

* Inlet Pressure : 0.4 MPa

* Application : Classification, Concentration of Middle size Particle

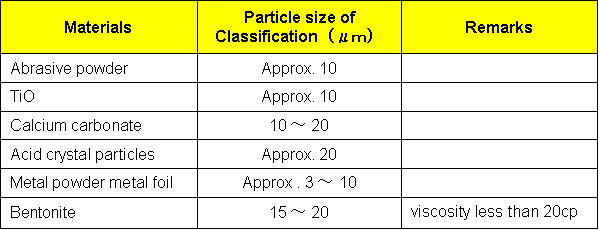

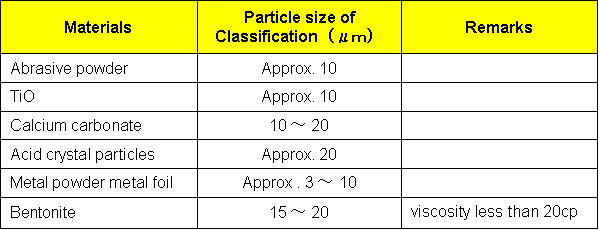

Model : SC-150 Cyclone Pump Set

Applications

* Separation & Classification of medium & large sized powder

in various ceramic

materials Classification of medium & large sized powder in abrasives

* Classification of medium & large sized metal powder (8 ~ 20μm Cut

of bronze,

ron, & other metal powders)

* Separating, removal of large sized powders in large specific gravity

powders

* Removal of laminated powder from the scales-shaped minerals powders

Features

* Separations of large specific gravity powders sized at 20 to 50 μm,

which can

hardly separated by Centrifuges, or Vibration sieves, can be done.

* Energy cost can be saved for low input pressure driving.

* Small compact size system with large capacity is offered.

* Very Stable, Simple and easy operation can be done.

* Free from the problems like screen damages of vibrating screen

* Selected materials are used against the high abrasion nature of big

size, or metal

particles

|

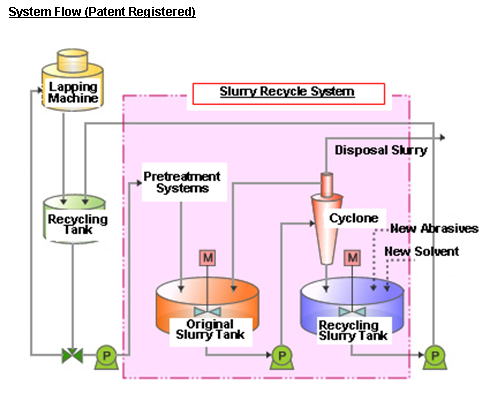

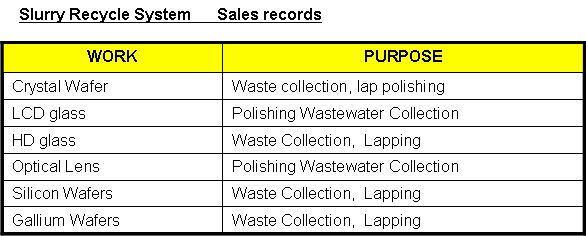

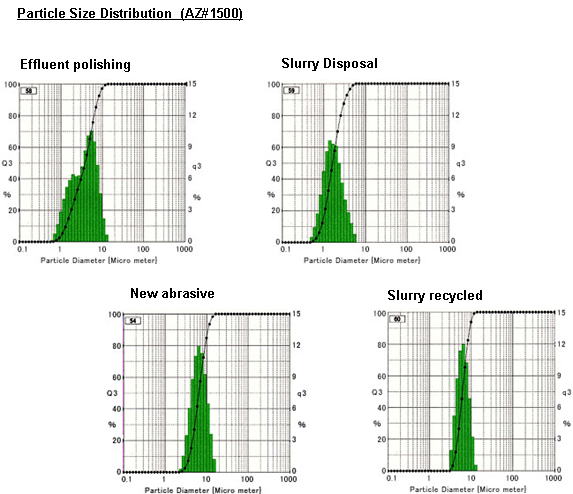

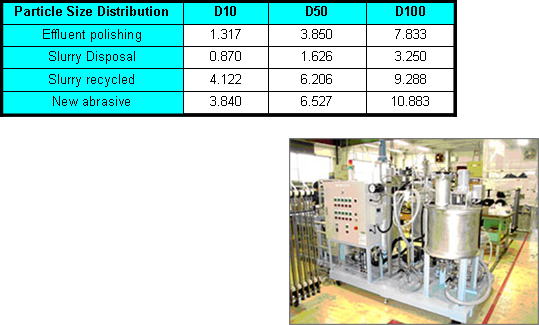

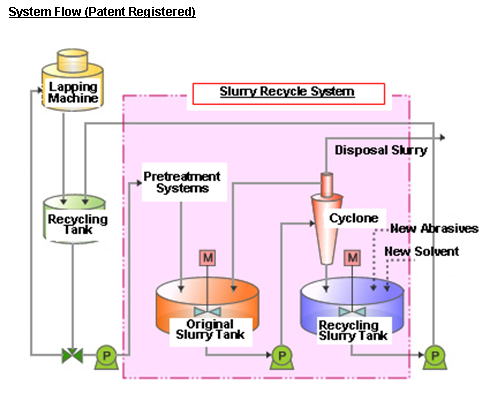

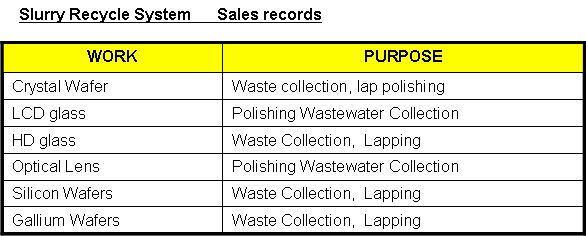

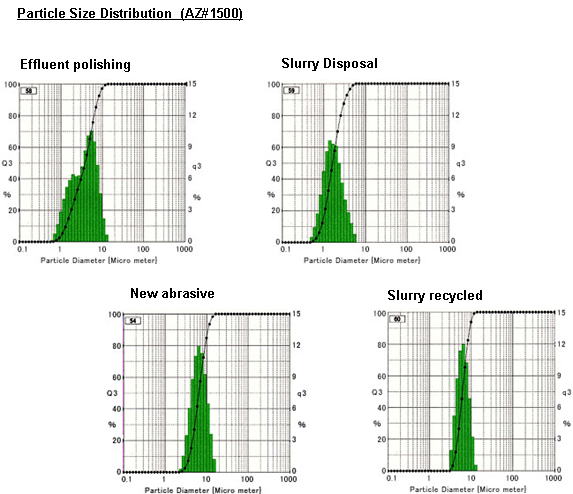

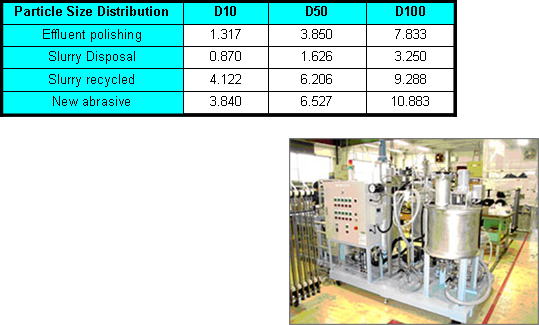

■ Slurry Recycle System

* Remove Chips, and Fragments from Lapping, polishing process

* High Removal efficiency, 50 to 80% recovery of the abrasive powder

Semiconductor wafers

Glass substrate

Quartz substratege

|

Copyright(C) 2007 FT Associates, Inc. All rights reserved. |