DISPERSING / EMULSIFYING / NANO FORMING / CRUSHING / PULVERIZING / DEGASSING

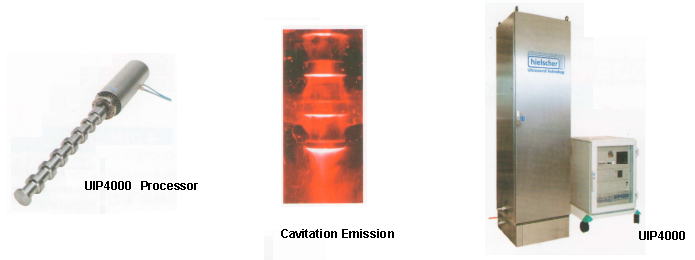

Ultrasonic Processor Nano Forming System

|

■ Feature

The Ultrasonic Processor Nano Forming System was developed and designed

by Hielscher (Germany), the specialized manufacturer of high power ultrasonic

equipment, for the dispersion, emulsifying, nano forming ,crushing, pulverizing,

degassing, & others.

Wide range of modes, from compact laboratory equipment to large-scale equipment,

are proposed and can be offered to the industries such as the food, chemical

and electronics, magnetic materials and others.

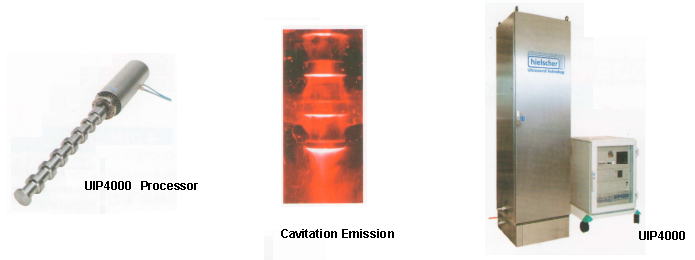

Without using the media for dispersing and grinding, and using ultrasonic

cavitation effects, the slurry is effectively processed for necessary nano

particles forming without contaminations.

Operation in batch system, continuous processing system from laboratory

Beaker test level to large scaled industrial production stage can be available.

There is no energy loss occurred by internal heat generation, and high

efficiency is achieved. [Patent registered] 24 hours of continuous operation.

Operation without any loda can be permitted, and it can be ran even in

the air. [Patent registered]

The output per unit is high, and the larger size pipes are usable for the

slurry.

The interface before and after the Ultrasonic Processor Nano Forming System

is very simple and easy. Which makes total operation system planning

very flexible.

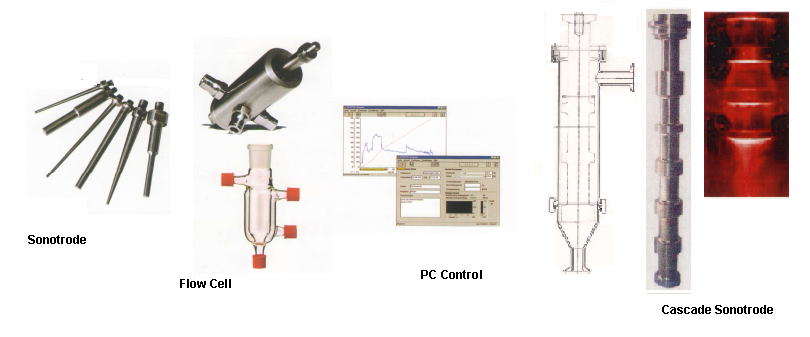

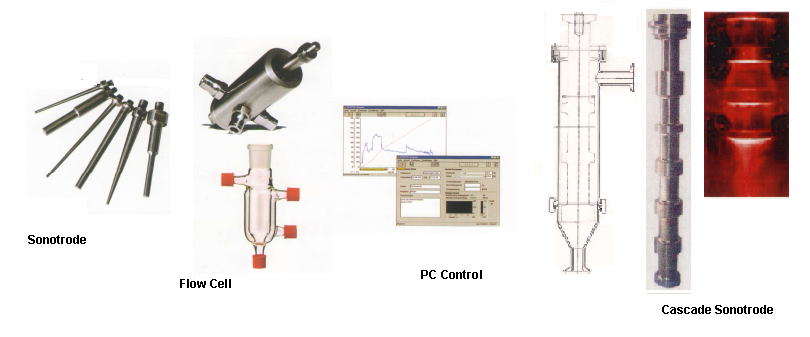

Various Related accessories / devices are offered. And the most suitable

system can be selected for your own requirement. Simple, but safety structure

is adopted. No operations under the high pressure is requested.

It can be applied to various particle sizes and wide range applications.

No moving part- is adopted. Overhaul and cleaning is so easy and simple.

Wide range of lineups has been introduced for experimental operation to

industrial production for various applications PC control system can monitor

various data, output, operation time, etc., is possible.

|

|

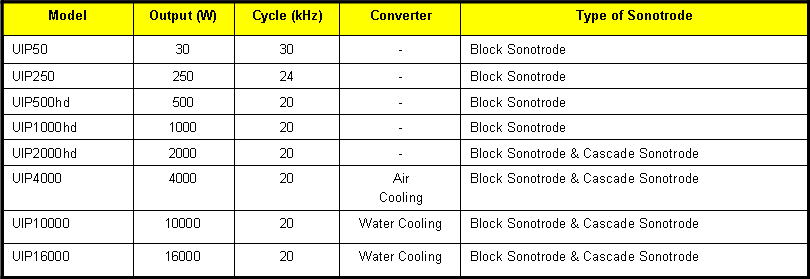

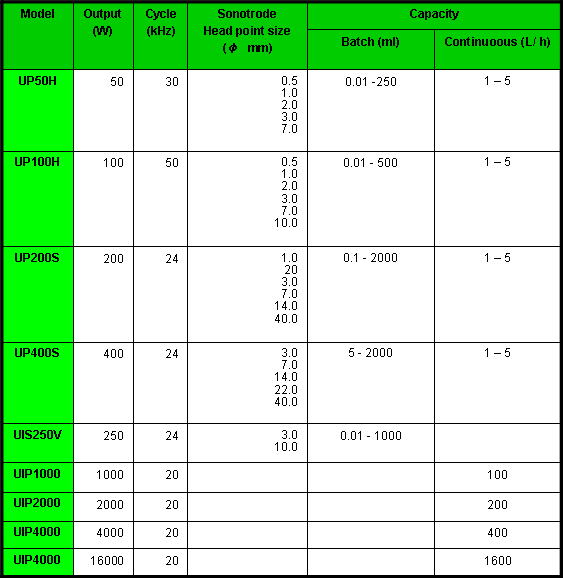

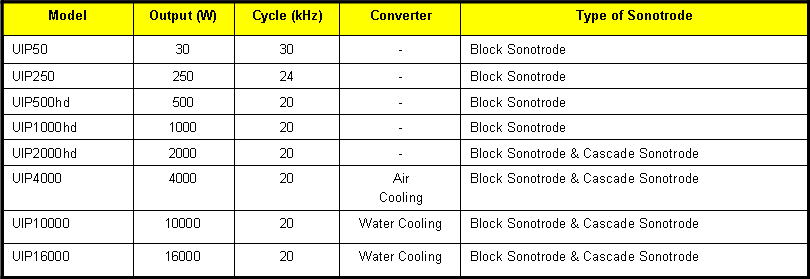

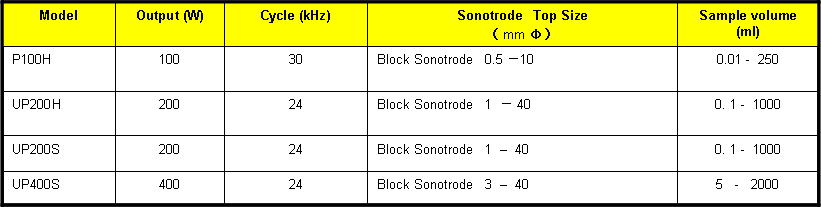

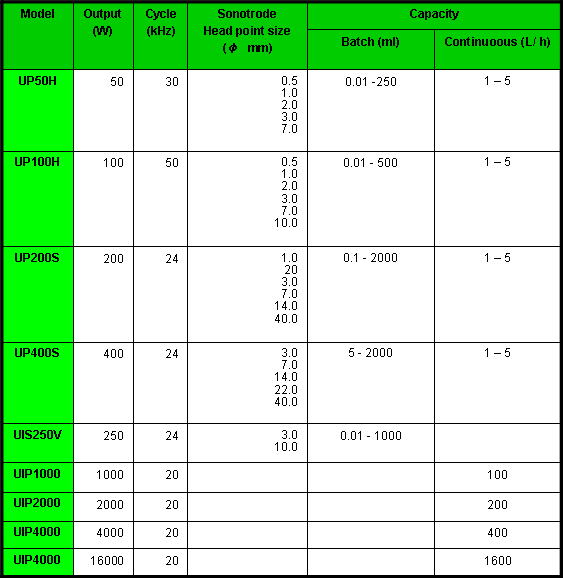

■ Major Models - Production Unit

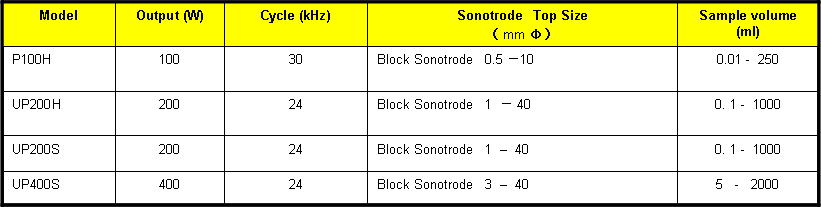

■ Major Models - Laboratory Unit

|

■ Applications

Ink pigments, Aluminum oxide, Indium Tin Oxide, Zinc oxide, Tin oxide,

Titanium oxide, Iron oxide, Ceramics,

Various metal (nickel, manganese and cobalt, platinum, gold, silver),

Silica, Zeolite, Teflon, Silicon, Carbon black, CNT, Dye, Abrasives, Coatings,

Emulsifying of Oil and Water, Food, Fuel, Adhesives,

Organic synthesis Activation of Catalyst,

Various polymers, Chemical reaction Powerful Cleaning, Washing, Peeling

Extraction of ingredient Uniformity of Particle size,

Crushing of bacteria, virus

|

■ Laboratory Units

Removable Handy Operation & Fixed Stand Operation can be offered.

24 hours of continuous operation is also possible.

Easy Operataion can be done from the main menu.

The Power Unit, & Transmission Unit are isolated.

It is also possible to set the Power Generation portion separately.

It can be used for Dispersion, emulsification, dissolution, cell disruption,

degassing, extraction, and various catalytic reactions, in various applications,

Using Touch panel, & Network connection, you can also easily accommodate

data management.

Customers various demands can be realized by various transmitters, soundproof

box, & other options.

Based on the data of the Laboratory, small Experimental Production unit,&

extensive experience, the scale up to the large suitasble production system

can be offered.

|

|

Copyright(C) 2007 FT Associates, Inc. All rights reserved. |